Self-Locking Nylon Cable Ties.

At Hoods Corporation, we pride ourselves on being a premier cable tie manufacturer in India, committed to delivering high-quality, heavy-duty industrial-grade self-locking nylon cable ties. As a major nylon 66 cable ties supplier, we serve industries worldwide, ensuring superior cable management, organization, and security. Our products, also known as zip ties, Ty-wraps, or plastic tie wraps, are engineered for robust performance in the most demanding environments, including cable management, automotive, packaging, electrical, and aircraft building.

Raw Material:

Our cable ties are made from Nylon 66, which is a superb wear and abrasion resistant material and well suited to machining. It has high mechanical strength, good sliding properties, good creep stability and is resistant to many oils and chemicals.

To meet diverse industry needs, we also offer specialized grades:

UV-resistant grades: For outdoor use, our UV-stabilized ties resist degradation from prolonged sunlight exposure, ensuring long-term performance in outdoor and solar energy applications.

Fire-resistant grades: These are crucial for electrical installations and other applications where fire safety is a concern. Our products are designed to be self-extinguishing, meeting stringent flammability standards.

Heat-stabilized grades: These ties can withstand continuous high temperatures, making them suitable for use in engines, appliances, and other high-heat environments.

We offer a comprehensive range of cable ties to cater to every application, from simple bundling to complex industrial harnesses. Whether you need a short cable tie 100 mm or a long cable tie 500 mm, we have the right size. Our product lineup includes lengths upto 920mm zip ties, perfect for large bundles and demanding tasks.

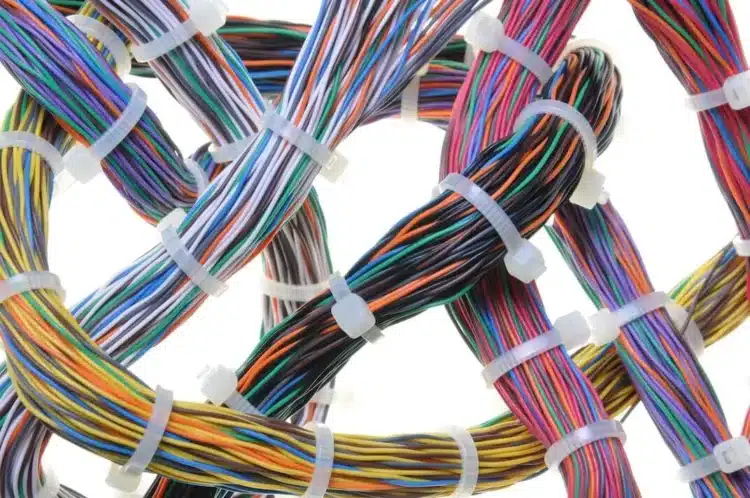

Organize with Our Wide Color Selection

Our coloured cable ties are more than just a visual option. They’re a practical tool for color-coding and organization. We offer a wide array of colors, including vibrant orange cable ties. This allows for easy identification of different circuits, cables, or systems.

Wide range of color cable ties are available starting from, Natural ● Orange ● Yellow ● Green ● Red ● Blue ● Black ● and more.

You can also check our Stainless steel cable ties , Reusable Cable ties and Security seal which comes with a unique printing and coding option

Nylon Cable Tie Sizes and Specifications

Operating Temperature

▬ Nylon 66 : Max 85°C / Min – 40°C

▬ Nylon 66 Heat Resistant: Max 120°C / Min – 40°C

▬ Nylon 66 UV: Max 85°C / Min – 40°C

Industrial Sizes

Product Code | Length (L) (mm) | Width (W) (mm) | Thickness (mm) | Bundle Dia (E) (mm) | Min. Tensile (kgs) | Pieces / Bag | Bags / Box | Box Weight (kgs) |

|---|---|---|---|---|---|---|---|---|

HS-100-IK | 104 | 2.5 | 1.05 | 23 | 8 | 1000 | 70 | 20 |

HS-100-I | 104 | 2.5 | 1.05 | 23 | 8 | 100 | 500 | 20 |

HS-150-I | 153 | 3.6 | 1.2 | 38 | 18 | 100 | 250 | 20 |

HS-200-I | 203 | 3.6 | 1.25 | 51 | 18 | 100 | 200 | 20 |

HS-250-I | 252 | 3.6 | 1.25 | 70 | 18 | 100 | 180 | 20 |

HS-300-I | 300 | 4.8 | 1.35 | 83 | 22 | 100 | 130 | 20 |

HS-370-I | 370 | 4.8 | 1.35 | 104 | 22 | 100 | 95 | 20 |

HS-400-I | 400 | 4.2 | 1.36 | 115 | 22 | 100 | 95 | 20 |

HS-450-I | 450 | 4.8 | 1.36 | 130 | 22 | 100 | 80 | 20 |

HS-500-I | 500 | 4.8 | 1.36 | 150 | 22 | 100 | 70 | 20 |

HS-550-I | 550 | 9 | 1.6 | 160 | 80 | 100 | 30 | 20 |

HS-630-I | 630 | 9 | 1.6 | 190 | 80 | 100 | 20 | 20 |

HS-760-I | 760 | 9 | 1.6 | 225 | 80 | 100 | 20 | 20 |

HS-920-I | 920 | 9 | 1.6 | 265 | 80 | 100 | 20 | 20 |

Other Sizes

Product Code | Length (L) (mm) | Width (W) (mm) | Thickness (mm) | Bundle Dia (E) (mm) | Min. Tensile (kgs) | Pieces / Bag | Bags / Box | Box Weight (kgs) |

|---|---|---|---|---|---|---|---|---|

| HS-200-S | 200 | 4.8 | 1.25 | 52 | 22 | 100 | 170 | 23 |

| HS-250-S | 250 | 4.8 | 1.3 | 69 | 22 | 100 | 150 | 25 |

| HS-150-LT | 150 | 2.5 | 1.1 | 35 | 8 | 100 | 400 | 19 |

| HS-200-LT | 200 | 2.5 | 1.1 | 50 | 8 | 100 | 350 | 22 |

| HS-300-LT | 300 | 3.6 | 1.25 | 80 | 18 | 100 | 175 | 25 |

HS-350-LT | 350 | 3.6 | 1.25 | 90 | 18 | 100 | 160 | 25 |

Heavy Duty Sizes

| Product Code | Length (L) (mm) | Width (W) (mm) | Thickness (mm) | Bundle Dia (E) (mm) | Min. Tensile (kgs) | Pieces / Bag | Bags / Box | Box Weight (kgs) |

|---|---|---|---|---|---|---|---|---|

| HS-150-HT | 150 | 7.6 | 1.35 | 35 | 18 | 100 | 250 | 20 |

| HS-200-HT | 200 | 7.6 | 1.35 | 50 | 18 | 100 | 200 | 20 |

| HS-250-HT | 250 | 7.6 | 1.35 | 65 | 18 | 100 | 180 | 20 |

| HS-300-HT | 300 | 7.6 | 1.35 | 80 | 22 | 100 | 130 | 20 |

| HS-370-HT | 370 | 7.6 | 1.35 | 104 | 22 | 100 | 95 | 20 |

| HS-400-HT | 400 | 7.6 | 1.35 | 115 | 22 | 100 | 95 | 20 |

| HS-430-HT | 430 | 7.6 | 1.35 | 145 | 22 | 100 | 80 | 20 |

| HS-530-HT | 530 | 7.6 | 1.35 | 150 | 22 | 100 | 70 | 20 |

Frequently Asked Questions about Nylon Cable Ties

Firstly, the raw material of cable tie is very important, always look for nylon 66 or PA66 cable ties, these cable ties are much superior to PA6 or nylon 6 or just nylon cable ties in terms of tensile strength, weather resistance and locking strength.

Secondly, the actual width of cable ties decides the tensile strength of the product.

Thirdly, since cable ties are manufactured in huge numbers, only high quality machinery, manpower, test equipments, quality management ensure that each and every piece is defect-free which in turn saves lot of time and hassle for our customers.

UV-stabilised or UV protected cable ties are certified for prolonged use under direct sunlight, life expectancy can be variable in different regions, however, they perform better than standard cable ties under sunlight.

For a 20ft container, Max 40 days. For 40ft container, Max 60 days. Local domestic supplies, Max 7 days. However, we have ample stocks for immediate shipment as well.

With 100% defect free product, yes, we are the first choice for quality cable ties for OEM and branded goods manufacturers.

Yes, one year replacement guarantee against any manufacturing defect.

Measure the Outer Diameter of the item that you need to bind or bunch together, find the bundle diameter of cable tie from the list below and select the length. Find the max strength required to hold the product, which is the addition of product weight on each cable tie and shock weight, match it with Min. tensile strength and find the width. Go to our catlog, match these and order using the product code.

Please send us your requirement to gopal@hoodscorp.com or WhatsApp your visiting card in the link below. We will share our agent’s or dealer’s contact located nearest to you.

Cable Tie was first invented by Thomas & Betts in 1958.

HS code for nylon cable ties is 39239090.